Advanced Manufacturing Research

Manufacturing & Materials Research Resources

The video slide sequence gives an overview of existing resources available to MIE faculty and students, as well as to academic and industry partners to support research in materials science & engineering and in advanced manufacturing.

Additive Manufacturing Related Research Examples

Additive manufacturing research in MIE includes developing and characterizing powders of new alloys as well as advanced materials characterization and structural integrity assessment of 3D-printed outcomes. The video slide sequence illustrates some of the approaches and examples.

Replication-Based Manufacturing

Replication-based, multi-scale (mezo/micro/nano) manufacturing technologies have been developed and used at MIE for several years. The video slide sequence illustrates some of the methods and examples of outcomes.

Composites Research Examples

Composites research in MIE includes the development and characterization of new self-healing and smart composite materials, as well as joining technologies for thermoplastics and thermosets. The video slide sequence illustrates some examples.

Ceramic Micro-Combustor

For more information please contact Prof. Ingmar Schoegl

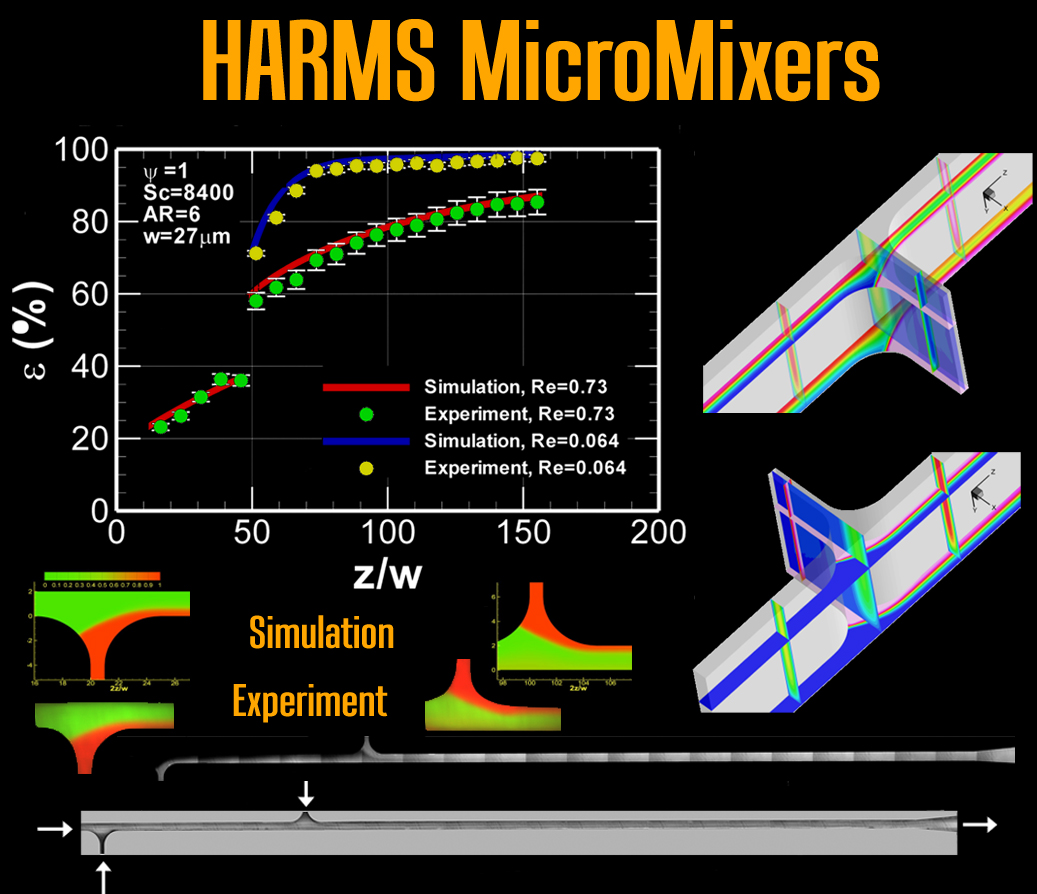

High-Aspect-Ratio Micro-Mixers

High-aspect-ratio microstructures (HARMS) provide significant advantages for simple diffusion-based micro-scale mixing devices. When optimized for mixing performance and pressure drop they can outperform many more complex and expensive alternatives. These micro-mixers can be mass-produced in polymer materials using replication-based, micro-manufacturing technology. For further information contact Prof. Dimitris E. Nikitopoulos.

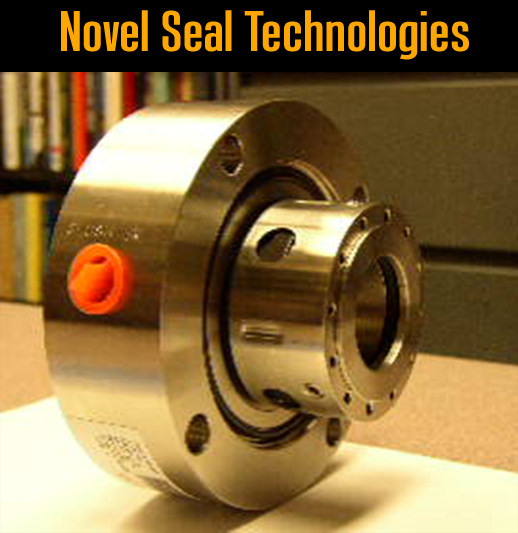

Novel Prototype Seals

Novel high-durability seals cooled by integrated micro-manufactured heat transfer features are developed in the Center for Rotating Machinery (CeRoM). The advantages are dramatic reduction in seal interface temperature, elimination of the need to flush for cooling, improved reliability and performance along with reduced emissions, and more uniform heat removal from the seal interface resulting in improved long-term flatness. For further information contact Prof. Michael M. Khonsari.

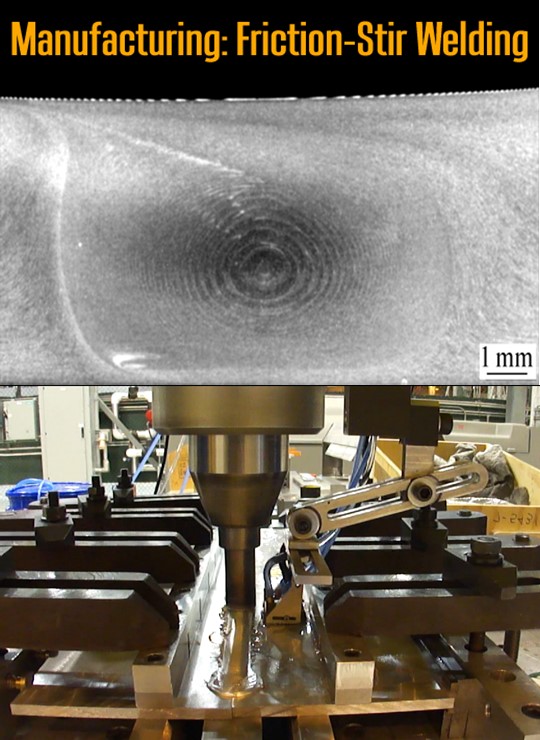

Friction-Stir-Welding

Friction-Stir Welding (FSW) is a joining technology widely used to seamlessly weld together Aluminum plates and parts for several applications. Process control and optimization as well as in-situ quality assessment is developed with the aid of modeling and simulation for improved joining effectiveness and strength. For further information contact Prof. M. A. Wahab.

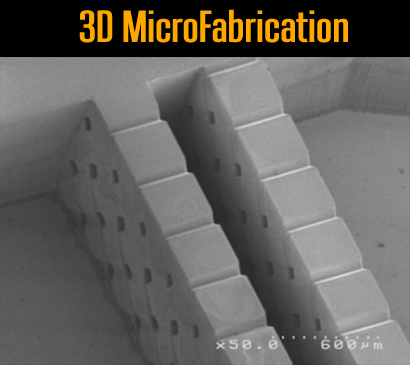

3D Micro-Fabrication

Three-dimensional micro-fabricated structures such as a 3D micro-fabricated mixer are realized using Su-8 LiGA (Lithographie Galvanoformung Abformung) micro-fabrication with angled exposure. For further information contact Prof. Wanjun Wang.

HARMS Micro-Gyroscope

A high-aspect ratio, micro-scale gyroscope was micro-fabricated using LiGA (Lithographie Galvanoformung Abformung). The LiGA method enables realization of High Aspect Ratio Micro-Structures (HARMS). For further information contact Prof. Michael C. Murphy.

Micro-Channel Heat Exchangers

Micro-channel heat exchangers are manufactured using replication-based, micro-metal-forming methods. These methods, which enable High Aspect Ratio Micro-Structure (HARMS) realization, employ novel coating and metal-to-metal bonding technologies. Materials used include copper and aluminum. For further information contact Prof. Wenjin Meng.

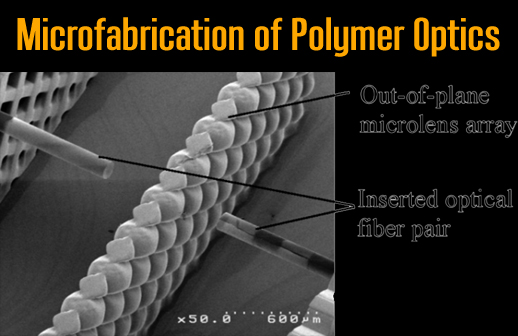

Micro-Fabricated Micro-Lens Arrays

Three-dimensional micro-fabricated structures such as a in-channel micro-lens arrays for bio-molecular detection applications are realized using LiGA (Lithographie Galvanoformung Abformung) micro-fabrication using angled exposure techniques. For further information contact Prof. Wanjun Wang.

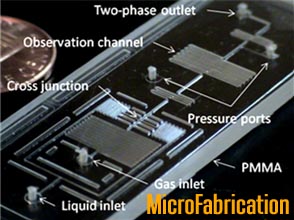

Polymer Micro-Fluidic Chips

Complex micro-fluidic chips with integrated functional elements are designed and micro-manufactured for a variety of applications including biological assays, porous media surrogates, drug screening etc.. The micro-manufacturing methods used are based on replication, which is cost-effective as it enables continuous mass production. This is achieved through the design and use of micro-embossing with mold inserts made either through micro-milling or LiGA (Lithographie Galvanoformung Abformung) micro-fabrication. For further information contact Prof. Dimitris E. Nikitopoulos or Dr. Daniel S. Park.

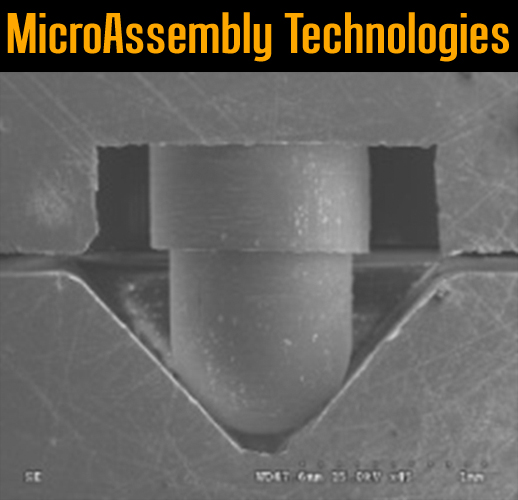

Alignment Features for Modular Micro-Chip Assemblies

Multi-module, stacked, micro-fluidic chips with integrated functional modules require precise alignment to ensure fluidic and electrical interconnections. To this end, passive-feature alignment technology on the microscale is developed. Alignment features are micro-manufactured with high-precision using replication-based methods employing micro-embossing with mold inserts made by micro-milling. For further information contact Prof. Michael C. Murphy or Dr. Daniel S. Park.

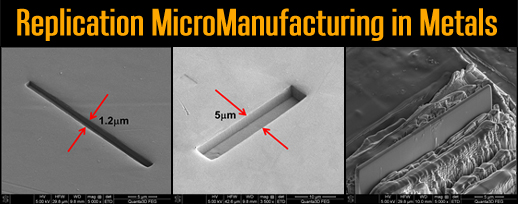

Micro-Scale Embossing in Metal

High-fidelity embossing in metals at the lowest end of the micron scale, O(1micron), is achieved using molding tools fabricated through the use of a Focused-Ion-Beam. For further information contact Prof. Wenjin Meng.

Electrospay of Novel Coatings

Novel coatings,including ones used as thermal barriers to protect metal parts for high temperature applications (e.g. gas turbines), are made using electrospray methods and in a related facility. For further information contact Prof. Shengmin Guo.

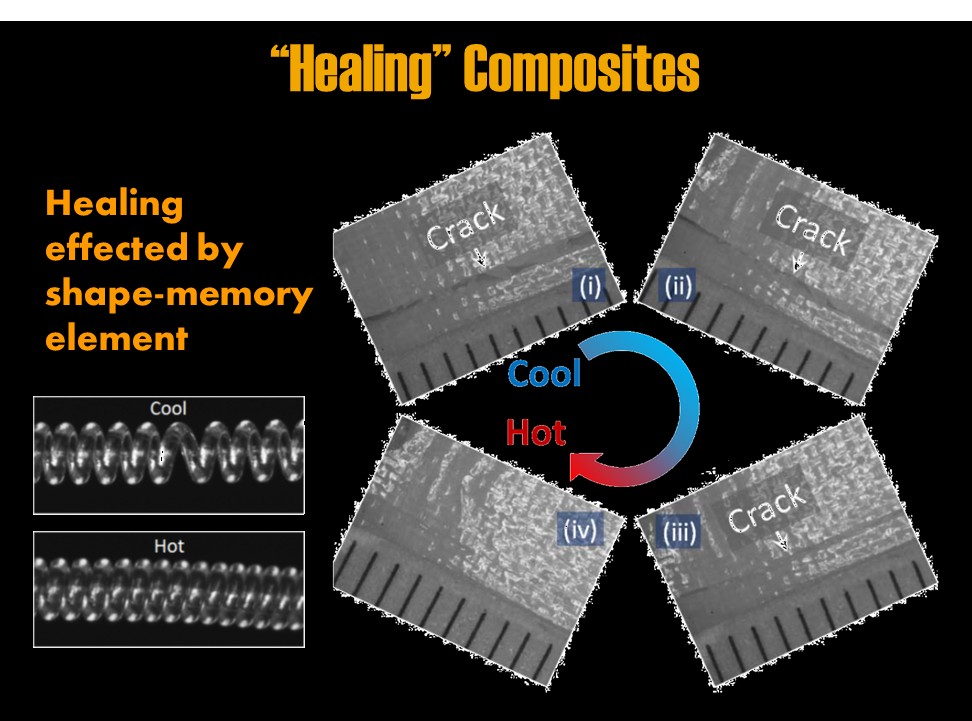

"Healing" Smart Composites

Novel "healing" smart composites are developed by creatively employing shape-memory additive elements to the composite matrix. Cracks are "healed" in-site by simple thermal treatment. For further information contact Prof. Guoqiang Li.

Joining of Thermoset and Thermoplastic Composites

Joining technologies using ultrasonic techniques are applied to achieve high-fidelity

joining of thermoplastic composites. This technique also applies to thermosets as

well as other types of composite materials. For further information contact Prof. Geneviève Palardy.

* Image shown is from Prof. Palardy's work at TU Delft before joining LSU.